CNC Machining Service

Machined prototypes and production parts delivered on time

CERTIFICATIONS

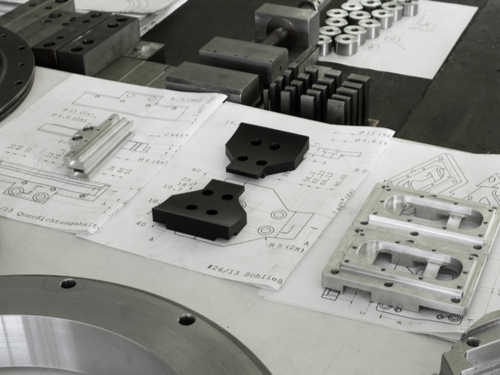

Renderfact CNC Machining

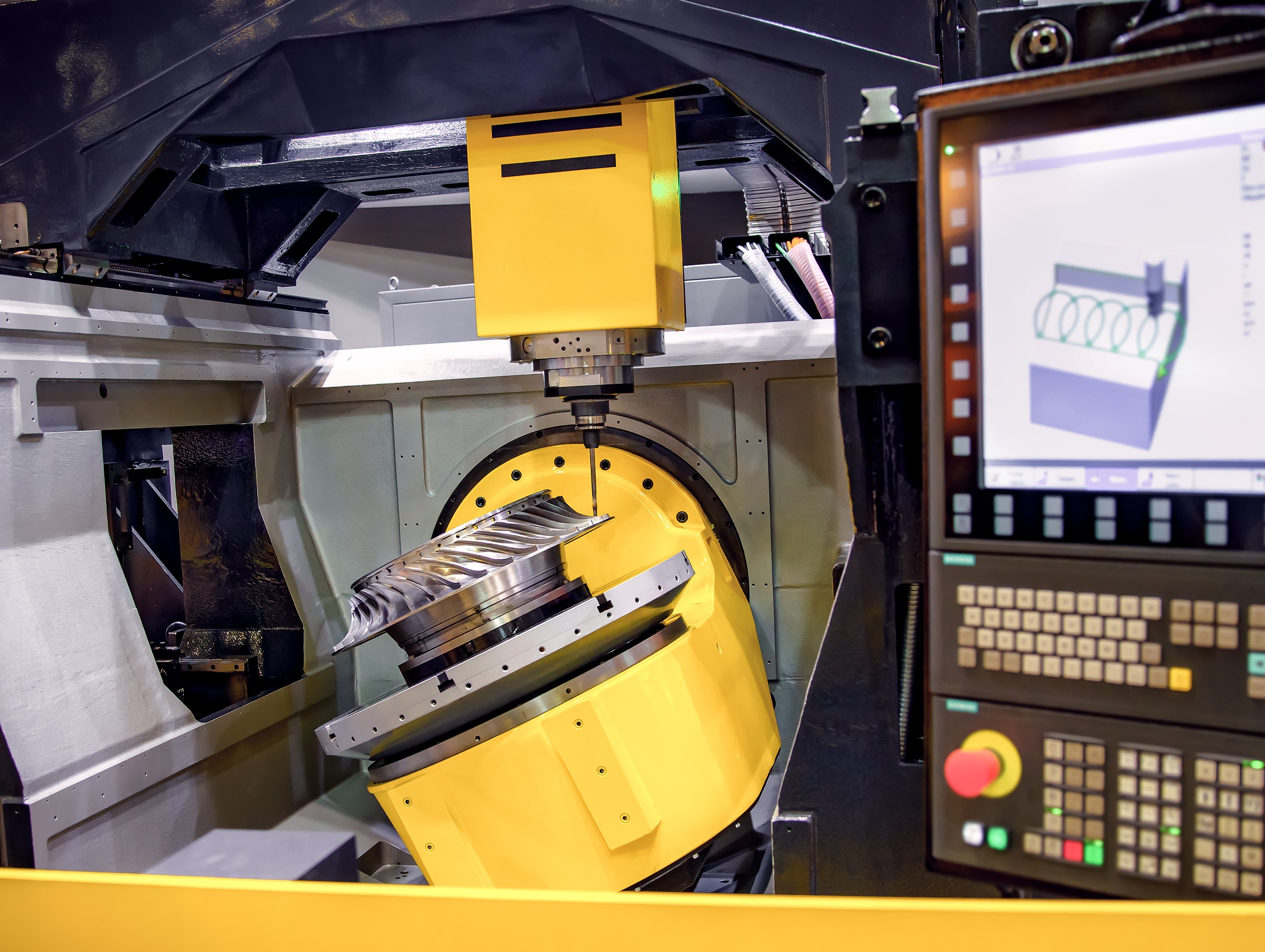

At Renderfact, we use advanced equipment to offer you a variety of CNC machining services including milling, turning, swiss machining, surface grinding and much more. Regardless of the manufacturing process used to create the end-use part, CNC machining is widely used by designers as a means of creating early and late-stage prototypes with short turnarounds times. Prototyping in CNC allows designers to rapidly iterate ideas without expensive tooling or longer wait times. Compared with other rapid prototyping methods, rapid CNC machining allows us to get tighter tolerances in prototypes in real materials fast. Using our state-of-art 3, 4 and 5-axis CNC machining centers, our team of engineers and machinists program the equipment to optimize cutting time, surface finish and final tolerance to meet your specifications.

CNC Prototyping is the preferred option to bring new design to life among the other rapid prototyping methods unless the products are designed for 3D printing or other methods only.

Below are some of the benefits of CNC Machining and How it Works!

Advantages of CNC Machining

Rapid Prototyping

Production and scalability

Cost Effectiveness

Precision

Safety

Selection of materials

CNC Milling Services

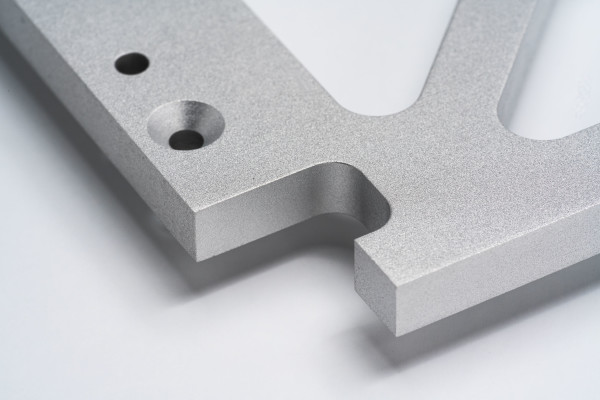

The CNC milling machine combines the accuracy of computerized controls to rotate and position multi-point cutting tools. CNC milling machines are built for precise manufacturing and repeatability which makes them perfect for rapid prototyping and low-to-high volume production runs. CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic material inside the CNC mill. Using G-code, the CNC machine is programmed to rapidly mill out parts from the block of raw material until you have the final shape you want.

Our 3- and 5-axis CNC machines are equipped with various toolsets to maximize efficiency and production speed. For intricate and complex geometries, a 5-axis CNC milling machine will move along three linear axes while simultaneously moving along two rotational axes. CNC mills can also work with a variety of materials from basic aluminum and plastics to more exotic ones like titanium — making them the ideal machine for almost any job. When the run is complete and your required surface finish is applied, parts are ready to be packed and shipped.

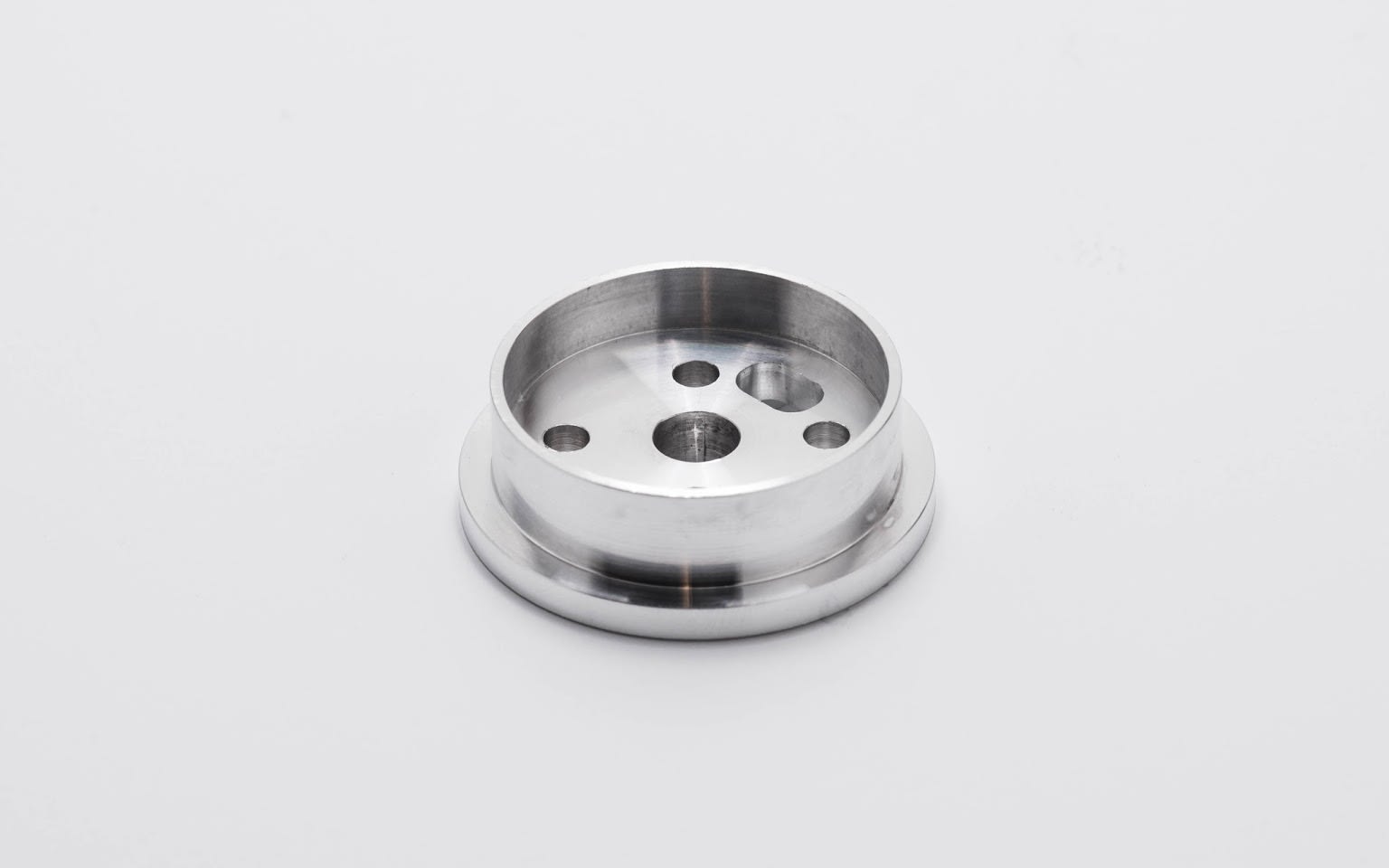

CNC Turning

Like CNC mills, CNC lathes can be easily set up for high repeatability, which makes them great for everything from rapid prototyping to low and high-volume production. CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret, with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result. This is also called “subtraction machining” since it involves material removal.

Our Multi-axis CNC turning centers allow for multiple machining operations to produce cylindrical parts with external and internal features, such as slots, tapers, and threads, etc. making them a cost-effective option for complex geometries that would otherwise require multiple machines or tool changes in a traditional machine. Render fact’s turning capability will allow you to produce highly accurate, high quality parts to meet even your most demanding requirements.

CNC Swiss Machining

A Swiss CNC machine is a modern precision manufacturing machine that can produce extremely small parts quickly and accurately. CNC Swiss turning machines have a sliding headstock that operates with a guide bushing, which provides excellent stability for the bar stock while complex slots, holes, threads and multiple diameters are machined into the workpiece. CNC (computer numerical controls) allow our Swiss turning equipment to be highly automated, providing consistent, precise parts at tight tolerances from the first component off the machine to the final production unit.

Swiss machines have exploded in popularity within precision manufacturing. The combination of high precision and high production volume make Swiss machines a critical piece of equipment for shops that want to produce a large volume of small and intricate parts with little margin for error. Render fact’s Swiss Machining capabilities allow producing high quality and extremely precise parts for industries such as aerospace, electronics, firearms, automotive, hydraulics, and medical.

Brass Parts

Brass machining is used in a wide variety of applications and industries, including medical, electrical, plumbing, and even consumer goods. Companies prefer small brass turned parts and components because it is one of the easiest materials to machine, it is cost efficient, and extremely durable. Machined brass fittings are often used in electronic hardware because of its low strength and weight properties. Additional brass machining applications include engineering, plumbing, and steam work because machined brass fittings have a low friction coefficient and high corrosion resistant properties.

Renderfact is a medium to high volume brass Components supplier who produce not only Brass Turned Parts but also brass inserts, electronics components, brass fasteners, brass casting and forged components, brass connector pin, brass hardware, brass fittings, brass auto component, brass electrical component, brass gas component, brass cable glands and brass component assembly.

The varied products we manufacture are in high demand persistently meeting our client’s expectations in brass parts product performance, service and delivery. Our company caters to an enormous clientele network. We can deliver to a customer base with the aid of an extraordinarily dexterous workforce that is proficient and dedicated.

Materials

CNC machining works on hard metals such as stainless steel and titanium, soft metals like aluminum, copper, and brass, and plastics including ABS, polycarbonate, nylon, acrylic, etc.

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Aluminum 6061

- Aluminum 6061-T651

- Aluminum 6063

- Aluminum 7075

- Aluminum 6082

- Aluminum 2024

- Aluminum 5052

- Aluminum 5083

- Aluminum ADC12 (A380)

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Copper

- Copper 101

- Copper for EDM

- Beryllium copper

- Chromium zirconium copper

- Tungsten copper

- Antimony copper

Brass / Bronze

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

- Brass 2680

- Brass H59

- Brass H62

- Brass 260

- Brass 385

- Brass CAD260

- Brass 360

- Tin phosphor bronze

- Aluminum bronze plate

- Tin bronze

Steel

Steel is an alloy of iron and carbon containing less than 2% carbon and 1% manganese and small amounts of silicon, phosphorus, sulphur and oxygen. It is used in every aspect of our lives; in cars and construction products, refrigerators and washing machines, cargo ships and surgical scalpels.

- 1045 Steel (45 #)

- 1008 Steel

- 1018 Steel

- 1020 Steel

- 1025 Steel

- 11Smn30 Steel

- 1215 Steel

- 4041 Steel

- 40Cr Steel

- 4130 Steel

- 4137 Steel

- 4140 Steel

- 42 Crmo Steel

- 4340 Steel

- 4J36 Steel Alloy

- 5140 Steel

- 5160 Steel

- 60Si2Mn Steel

- 65Mn Steel

- A2 Tool Steel

- A36 Steel

- C3600

- Cr12Mov Steel

- D2 mould steel

- DC-01 Steel Cold rolled steel

- EN16T Steel

- EN3B Steel

- EN8T Steel

- H13 Steel

- Inconel Steel

- Invar 36 Steel

- NAK80 Steel

- P20 Steel

- S136 Steel

- S7 Steel Tool Steel

- SK5 Steel

- SKD11 Steel

- SKD61 Steel

- SKH51 Steel

- ST37 (Q235) Steel

- ZGmn13-5

- Galvanized Steel / SGCC / SECC

- S7 Steel

- SCM440 (40CrMo) Steel alloy

- 52100 Bearing Steel

Stainless Steel

High tensile strength, corrosion and temperature resistant. Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished.

- SUS304 Stainless steel

- SUS303 Stainless steel

- SUS301 Stainless steel

- SUS316 Stainless steel

- SUS316L Stainless steel

- SUS401 Stainless steel

- SUS416L Stainless steel

- SUS416 Stainless steel

- SUS420 Stainless steel

- SUS201 Stainless steel

- SUS430 Stainless steel

- SUS431 Stainless steel

- SUS440C Stainless steel

- SUS410 Stainless steel

- SUS630 / 17-4PH Stainless steel

- PP631 / 17-7PH Stainless steel

Titanium

Titanium can be alloyed with iron, aluminium, vanadium, and molybdenum, among other elements, to produce strong, lightweight alloys for military, industrial processes automotive, agriculture (farming), medical prostheses, orthopedic implants, dental and endodontic instruments and files, dental implants, and other applications.

- TC4 Titannium Alloy

- TC5 Titanium Alloy

- Military-grade titanium Alloy

- Food-grade titanium Alloy

- R53400 Titanium Alloy 9

Plastics

- ABS

- PC

- ABS+PC

- PMMA

- POM

- PP

- PA

- PEEK

- PET

- PVC

- PPSU

- PPS

- PTFE

- PBT

- PE

- PEI

- HDPE

- UPE

- CPVC

- EPP

- FR-4

- HIPS

- LDPE

- PAI

- PETG

- PPA

- PS

- PVDF

- Bakelite

Standard Tolerances

If you do not provide us with your tolerances for CNC Machining, we use standard tolerances for metals DIN-2768-1-fine and DIN-2768-1-medium for plastics. Tolerances can be greatly affected by part geometry and type of material. Our design engineers will consult you on every part of the project and will try to provide you with the highest degree of precision possible.

General Tolerances to DIN ISO 2768

The latest DIN standard sheet version applies to all parts made to DIN standards.

Variations on dimensions without tolerance values are according to "DIN ISO 2768- mk".

GENERAL TOLERANCES FOR LINEAR AND ANGULAR DIMENSIONS(DIN ISO 2768 T1)

LINEAR DIMENSIONS:

| Permissible deviations in mm for ranges in nominal lengths | f(fine) | Tolerance class designation (description) | v(very coarse) | |

|---|---|---|---|---|

| m (medium) | c (coarse) | |||

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | - |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over 2000 up to 4000 | - | ±2.0 | ±4.0 | ±8.0 |

EXTERNAL RADIUS AND CHAMFER HEIGHTS

| Permissible deviations in mm for ranges in nominal lengths | f(fine) | Tolerance class designation (description) | v(very coarse) | |

|---|---|---|---|---|

| m (medium) | c (coarse) | |||

| 0.5 up to 3 | ±0.02 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

ANGULAR DIMENSIONS

| Permissible deviations in mm for ranges in nominal lengths | f(fine) | Tolerance class designation (description) | v(very coarse) | |

|---|---|---|---|---|

| m (medium) | c (coarse) | |||

| up to 10 | ±1º | ±1º | ±1º30' | ±3º |

| over 10 up to 50 | ±0º30' | ±0º30' | ±1º | ±2º |

| over 50 up to 120 | ±0º20 | ±0º20' | ±0º30' | ±1º |

| over 120 up to 400 | ±0º10' | ±0º10' | ±0º15' | ±0º30' |

| over 400 | ±0º5' | ±0º5' | ±0º10' | ±0º20 |

GENERAL TOLERANCES FOR FORM AND POSITION (DIN ISO 2768 T2)

STRAIGHTNESS AND FLATNESS

| Ranges in nominal lengths in mm | Tolerance class designation (description) | ||

|---|---|---|---|

| H | K | L | |

| up to 10 | 0.02 | 0.05 | 0.1 |

| over 10 up to 30 | 0.05 | 0.1 | 0.2 |

| over 30 up to 100 | 0.1 | 0.2 | 0.4 |

| over 100 up to 300 | 0.2 | 0.4 | 0.8 |

| over 300 up to 1000 | 0.3 | 0.6 | 1.2 |

| over 1000 up to 3000 | 0.4 | 0.8 | 1.2 |

PERPENDICULARITY

| Ranges in nominal lengths in mm | Tolerance class designation (description) | ||

|---|---|---|---|

| H | K | L | |

| up to 100 | 0.2 | 0.4 | 0.6 |

| over 100 up to 300 | 0.3 | 0.6 | 1 |

| over 300 up to 1000 | 0.4 | 0.8 | 1.5 |

| over 1000 up to 3000 | 0.5 | 0.8 | 2 |

SYMMETRY

| Ranges in nominal lengths in mm | Tolerance class designation (description) | ||

|---|---|---|---|

| H | K | L | |

| up to 100 | 0.5 | 0.6 | 0.6 |

| over 100 up to 300 | 0.5 | 0.6 | 1 |

| over 300 up to 1000 | 0.5 | 0.8 | 1.5 |

| over 1000 up to 3000 | 0.5 | 1 | 2 |

RUN-OUT

| Tolerance class designation (description) | ||

|---|---|---|

| H | K | L |

| 0.1 | 0.2 | 0.5 |

Finishes

Renderfact provides surface finishes on all CNC parts, including anodizing, electroplating, bead blasting, polishing, brushing, powder coating, and painting.

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Powder coating forms a durable, wear resistant and corrosion resistant layer on the surface of parts. Powder coating can be used to apply colors to parts and is compatible with any metal.

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. Most commonly applied to aluminum.

Painting the surface of a part improves its aesthetic appearance and can provide brand recognition to consumers. In addition, painting can have a protective effect on parts.

Applications

Rapid Tooling

Rapid tooling at Renderfact, you get to use the actual production grades of material, allowing you a much clearer picture of how the parts will act in real-world applications and enabling you to test and confirm you have made the correct material choices.

Rapid Prototyping

Rapid prototyping allows you to leverage the many advantages of computerized equipment to produce fast-turnaround prototypes, engineering models and high-quality end-use parts in the least possible time. Get in touch for your next rapid prototyping project.

End-Use Production

Renderfact is your ideal source for end use parts. Proven manufacturing processes like CNC Machining, and Injection Molding are complemented by our additive manufacturing capabilities like SLA, SLS, FDM, and DMLS, which provide you with incredible design freedom where complexity and small design iterations are not a roadblock.

Gallery

Quality Reports & Certifications

Full dimensional report

A Full work-up of dimensions can be provided for the parts you order for your peace of mind, on request.

Material certification

We have partnered with specialized Metallurgy Labs that provide and process special material certifications when requested.

First part verification

We provide first part verification services for a mutually agreed MOQ or on specific requests. We normally ship two sets of parts to the customer for verification and only once the parts have been validated, we move into full production.

Only 4 simple steps to complete your project. Follow the instruction and give it a try!