Diamond Cutting and Polishing Tools

Machined prototypes and production parts delivered on time

CERTIFICATIONS

RenderFact Diamond Cutting and Polishing Tools

India is the one of the main suppliers of finished diamonds to the world. It is said that 11 out of 12 diamonds set in any jewellery in the world are cut & polished in India. Gujarat alone houses 80% of all the processing of diamonds produced in the country, with a concentration of 90% in diamond cutting companies in the single city of Surat.

Renderfact is the one of the fastest growing and leading manufacturers of Diamond Cutting & Polishing Tools in Surat. Our first company was founded in 1990 and we have been providing service to our customers for more than 30 years with maintaining excellent customer service and reputation in the market.

We have expertise and experience in the manufacturing of all types of Diamond Polishing Press pots, Diamond Auto Polishing Ceramic Holder, 4P and Sawing Laser Machine Mechanism and its parts, Stages, Diamond Mapping Machine Dops. We have the best and state-of-art machines to provide the customer the best parts with ISO 9001:2015 standard Quality.

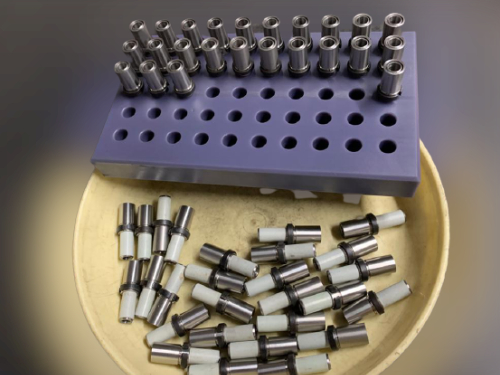

Top and Bottom Press Pot

With an aim to stand tall on the expectations of our esteemed clientele, we provide both Top & Bottom Press Pots with optimum quality and performance. The Bottom Press Pots are made from Leaded Steel Material. It is made in our Special Purpose Automatic Sliding head machine in a single operation under the supervision of our trained operators. Further, our products are checked on various parameters by our quality team before supplying it leaves our factory. These products are also provided at competitive prices. The features of our Press Pot include sturdy look, compact design, and are non-corrosive in nature. We provide precise bottom press pot with having ±0.01 MM tolerance. Our product are available in 3 or 4 slots as per your requirement.

Specification:

Bottom Press Pots are also available in Required Deepness.

| size | No. available as requirement |

|---|---|

| 5.mm | No. 8 to 38 |

| 6.mm | No. 22 to 50 |

| 7.mm | No. 32 to 60 |

| 8.mm | No. 62 to 70 |

| 9.mm | No. 72 to 80 |

| 10.mm | No. 82 to 90 |

| 12.mm | No. 91 to 110 |

| Deep: - 11%, 13%, 15%, 17%, 19%, 21%, 23%. | |

Diamond Scanning & Mapping Machine Dops

Every rough diamond has unique characteristics that can be determined using advanced diamond mapping technology. For instance, imaging scans the rough diamond to reveal its internal birthmarks, the diamond’s external surface with the help of software analyzes the rough diamond to explore the polished diamond’s aesthetic and financial value potential.

As a diamond cutting and polishing tool manufacturer, we produce these Galaxy Dops in which the roughs are held and then are put into the Galaxy Machine, where the scanning and planning of the rough is done, in terms how many diamonds can be worked out from the rough with its inclusions.

Stages

Now, there are machines out there that perform the most accurate scanning of groove and cavity of the Diamonds. It comes with specialized software for Precise planning, uniform, and sharp marking feature as well as customized text and logo marking. It is used to confidently plan and print manufacturing instructions for rough diamonds. It uses the latest of the art optical lens technology for diamond planning & marking solution. In this new generation system, a stage (on which the rough diamond is placed, is an essential tool for diamond processing to get efficient production.

At Renderfact, we supply all size of stages and holders, that are manufactured with high quality CNC machines at our state of art facilities.

Diamond Auto Polishing Ceramic Holder

Automatic Polishing Machines are basically robots that essentially manufacture round cut diamonds. The machine is equipped with an advanced Micro Controller for most precise and accurate polishing of facets with excellent symmetry and luster. Grain Seeking is automated along with Speed control is present to ensure best results. These Auto Polishing machines can polish 16 facets together along with 8 crowns and to hold these rough diamonds into place, specialized ceramic holders are needed, in which the diamonds are held and then are polished.

At Renderfact, we specialize in manufacturing these ceramic holders for the polishing machines that are used for holding the rough diamond.

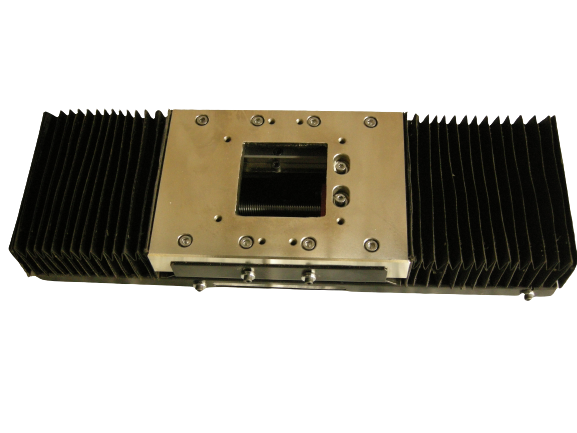

4P Laser cutting & Sawing Machine Mechanism.

Renderfact is an eminent manufacturer & supplier of the 4P Laser Cutting and sawing machine’s mechanism and its parts. Laser cutting is perfect blend of an advanced innovation with the best practices and must for all the Diamond Manufacturers around the World. These laser cutting machines take care of the sawing, shaping, blocking, and 4-in-1 process, and cut pre-planned rough diamonds. The result is always appreciable compared to what one gets from the conventional method of diamond planning and cutting.

At Renderfact, we also supply parts and offer assembly services for 4P Laser Cutting & Sawing machine.

Applications

Rapid Tooling

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which don't look even slightly believable.

Rapid Prototyping

Rapid prototyping allows you to leverage the many advantages of computerized equipment to produce fast-turnaround prototypes, engineering models and high-quality end-use parts in the least possible time. Get in touch for your next rapid prototyping project.

End-Use Production

Rapid tooling at Renderfact, you get to use the actual production grades of material, allowing you a much clearer picture of how the parts will act in real-world applications and enabling you to test and confirm you have made the correct material choices.

Gallery

Quality Reports & Certifications

Full dimensional report

A Full work-up of dimensions can be provided for the parts you order for your peace of mind, on request.

Material certification

We have partnered with specialized Metallurgy Labs that provide and process special material certifications when requested.

First part verification

We provide first part verification services for a mutually agreed MOQ or on specific requests. We normally ship two sets of parts to the customer for verification and only once the parts have been validated, we move into full production.

Only 4 simple steps to complete your project. Follow the instruction and give it a try!